It is no secret in the maritime industry that gas detectors are some of the most essential safety equipment required onboard vessels or offshore oil rigs. In these environments which are virtually made up of confined spaces and hazardous materials, gas leaks are a serious matter to be on the constant lookout for.

However, it is a well known fact that gas detectors and analyzers generally come in two forms: either a fixed system or a portable device. A fair question that comes to one’s mind when learning about this fact is, what exactly is the difference between the two?

Besides the obvious difference in portability, is there anything else that sets them apart? What are the advantages and disadvantages of both types of systems for the marine environment? What kind of detectors are most commonly used in the maritime industry and why? We will carefully explore various arguments and try to answer the most frequently asked questions about the differences between marine fixed and portable gas detectors in this article.

Key differences

To comprehend the differences between the two types of gas detection systems, we must first look at what each of them does individually.

Fixed gas detectors

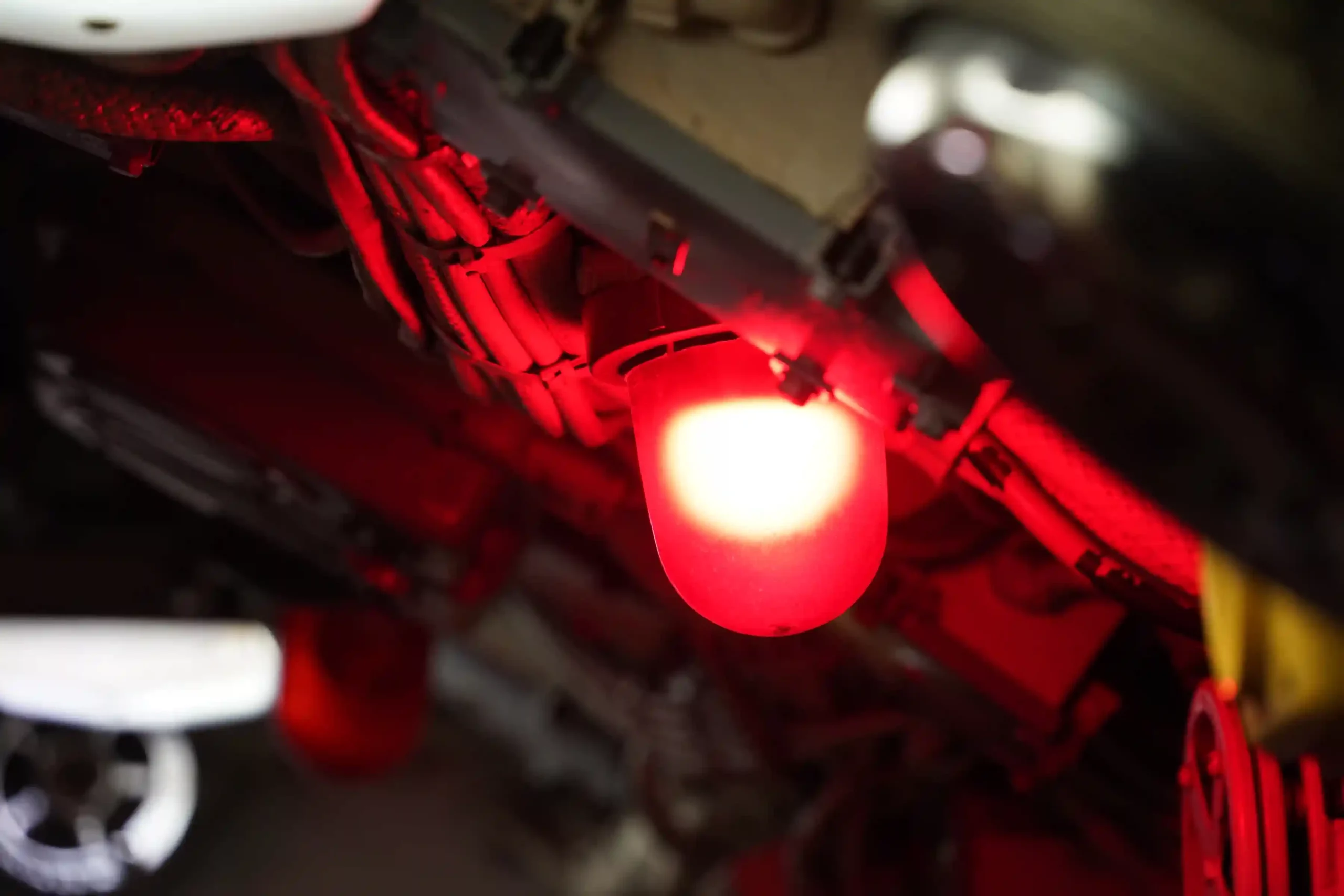

Fixed gas detectors are electronic systems installed permanently in one location. They are generally mounted on a wall in the area that needs to be monitored, hence they are sometimes also called wall-mounted detectors. Fixed gas detectors share similarities with fire and smoke detectors, in the sense that the sensors are connected to a control panel which identifies if gas concentration in the chamber reaches a specific level. Furthermore, the fixed gas detection systems are commonly linked to other safety systems which they trigger in case of a leak, resulting in audible and visual alarms, the opening of vents, closing of valves, or even the automatic shutting down of certain processes.

A fixed gas detection system comprises of gas detection sensor heads and transmitters connected to a control panel, which serves the role of a hub conducting various functions. Normally, the control panel is situated in a safe zone but it can also be installed in a hazardous area.

A downside of this type of gas monitoring system is the way it works, meaning it can only detect gases that diffuse into the sensor. A localized but abrupt leak may not be detected timely enough to prevent a member of the crew from coming in contact with the gas. Moreover, they also require to be hard-wired and connected to a power supply to function.

A more detailed summary of the advantages and disadvantages of marine fixed gas detection systems will be outlined below:

Pros:

- Round-the-clock, continuous monitoring of gas concentrations in air

- Loud, audible and bright, visual alarms

- Can be connected to other safety systems (e.g. exhaust fans)

Cons:

- Needs hard-wired power supply

- Limited function in certain situations (e.g. localized leaks)

Portable gas detectors

Portable gas detectors are designed for personal safety, monitoring the gas concentration in an area, only they are, as their name suggests, handheld, small and flexible. These lightweight electronics are carried or worn clipped to a clothing item by a crew member. As such, their range is limited to the breathing zone of the carrier/wearer, and they are not appropriate for monitoring larger areas continuously.

Portable gas detectors come in two types: single gas and multi gas detectors. They are an extremely reliable means of protecting crew members as they move through the rooms of the ship. This is due to their functionality, since they set off an audible or visible alarm when gas levels in the breathing area of the wearer exceed the permissible threshold. The crew member can then quickly evacuate and further take the necessary safety measures. The majority of portable gas detectors are battery powered.

However, they present a few disadvantages themselves. They are generally not connected to other safety systems, the way fixed gas detectors are. In other words, if the device issues an alarm, it is up to the crew member to take further action and mitigate the risk of a hazard.

We will highlight the main benefits and drawbacks of marine portable gas detectors in the lines below:

Pros:

- Portable, flexible and lightweight (can be easily carried in any room of the ship)

- Battery powered

Cons:

- Limited to the breathing zone of the crew member

- Not made for continuous monitoring of an area

- Crew needs proper training for using them

- Not connected to other safety systems

Now, even after reading through plenty of information about fixed and portable gas detectors, some of those operating in the marine industry might still be wondering: OK, both types are useful in specific contexts and have their own practicality; but still, which one do I need for my vessel or offshore rig?

As a rule of thumb, portable gas detectors are generally used to protect human lives, whereas fixed systems aim to safeguard the assets, in this case the vessel and the onboard equipment.

That being said, since portable gas detectors are mandatory and often found in numbers, the question above should be rephrased to “Does my vessel need fixed gas detectors as well?”.

Generally, yes.

There are numerous types of vessels sailing the world’s oceans, and they all differ from each other in their objective. And then, there are offshore oil rigs which are their own different category. So perhaps to tackle the above question correctly, one must look at each specific type of vessel and determine where fixed gas detectors fit within the scope of the vessel.

Check out our article which explores how different vessel types make use of fixed gas detection systems.

Moreover, read our blog for a wealth of information regarding vessels and electromechanical equipment and instrumentation used in the maritime industry.

Discover our marine gas detection solutions

Luckily, we can provide both fixed and portable gas detectors, should you decide to use these marine electronics on your vessels or offshore oil rigs. Furthermore, our service engineers can ensure they are properly tested, inspected, calibrated and certified before being deemed functional and ready to go.

Our offer also includes qualitative calibration gases with fast delivery in key areas worldwide, such as Singapore, ARA Region, Cardiff and Houston. Contact us and together we can address your pain points and help you succeed in your maritime journey.

Disclaimer

This article serves an informative purpose only and does not intend to drive purchase decisions towards either type of gas detection system. Both fixed and portable gas detectors have their uses, and ship owners and managers should take into account technical specificities and relevant regulations when installing these systems.