The role of the maritime industry for the global trade and economy is essential. Still, it is also a high-polluting industry due to the emissions from the vessels and their effect on the environment. Some of the standard emissions include nitrogen oxides (NOx), sulfur oxides (SOx), and carbon dioxides (CO2). Given the environmental challenges imposed by the ships’ operations, stricter regulations and innovative solutions emerged. One of the solutions is Exhaust Gas Cleaning Systems (EGCS), also called scrubbers.

Do you want to learn about scrubbers, how they work, and the applicable regulations? Then, enjoy the read!

What are scrubbers?

Scrubbers are designed to reduce air pollution by removing pollutants, particularly sulfur oxides (SOx), from the exhaust gases emitted by marine engines burning high-sulfur fuel oils.

Starting the 1st of January 2020, the International Maritime Organization (IMO) limits the sulfur in ships’ fuel oil to a maximum of 0.50%. In specific control emissions areas, the limit is even lower, set at 0.10%. One of the solutions the maritime industry can adopt to comply with the strict regulations are scrubber systems. These systems are essential in minimizing the sulfur oxides in the air that have a detrimental effect on the environment and human health.

What are the types of scrubbers?

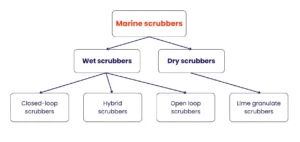

There are two main categories of scrubbers: wet and dry (Fig. 1). Wet scrubbers use liquid solutions to capture pollutants through absorption or dissolution, while dry scrubbers use solid sorbents to capture pollutants through adsorption or chemical reaction.

The wet scrubbers are further divided into open-loop, closed-loop, and hybrid categories.

- Open-loop scrubbers use seawater in the cleaning process.

- Closed-loop scrubbers use freshwater treated with chemical solutions in the cleaning process.

- Hybrid scrubbers leverage both closed and open modes, allowing for flexibility based on operational requirements and environmental regulations.

How do scrubbers work?

Wet Scrubbers

Open-loop Scrubbers

Open-loop scrubbers use seawater as both the scrubbing and neutralizing agent. The exhaust gas enters the scrubber system where it comes into contact with the seawater. For instance, when SOx reacts with water, it forms sulfuric acid. The alkaline nature of the seawater neutralizes the acid, removing the sulfur pollutants from the exhaust gases. The resulting wash water with the neutralized pollutants is treated within the scrubber before discharge into the sea. The discharged water must comply with the criteria in MEPC 184(59), including the pH, PAH (Polycyclic Aromatic Hydrocarbons), and turbidity.

While the system proves highly efficient, it demands a substantial pumping capacity due to the high amount of seawater necessary. Although an open loop configuration functions effectively when the seawater has adequate alkalinity, it is ineffective when using seawater at high ambient temperatures, fresh water, or brackish water.

Closed-loop Scrubbers

The operation of the closed-loop scrubbers resembles the open-loop scrubbers except that instead of seawater, a specific scrubbing medium is used (e.g., freshwater treated with chemical solutions). When pollutants like SOx pass through the medium, they interact with the water and form sulfuric acid. The acid is then neutralized by the alkaline nature of the medium. The resulting wash water is reused afterwards, circulating continuously within the closed loop. Still, before any discharge into the sea, the wash water is treated to remove any solid particles or residual pollutants.

Hybrid Scrubbers

Hybrid scrubbers can use both open-loop and closed-loop modes. This flexibility allows switching between modes based on operational requirements, regulations, and available scrubbing medium.

Dry Scrubbers

Dry scrubbers use dry sorbent material to remove sulfur, like pellets of hydrated lime. When the sorbent is injected in the exhaust system, it interacts with the SOx, forming reaction products. These products, along with any unreacted sorbent material are captured by particulate control devices. Afterwards, they are disposed of or recycled appropriately, depending on the specific system design and regulatory requirements.

The choice between wet and dry scrubbers depends on factors such as the type of pollutants, efficiency requirements, water usage considerations, and environmental regulations.

Calibration Gases for Scrubbers

Scrubbers are equipped with gas analysers that measure the composition of the exhaust gases before and after they pass through the scrubber. This equipment is essential in monitoring the SO2 emissions and ensuring the compliance with the IMO regulations. To validate the precise and accurate readings of the analysers, they have to be calibrated regularly.

Mr. Marine can supply both the most common SO2 calibration gases and customized mixtures tailored to your unique requirements. We can deliver the calibration gases same-day to you in Singapore and our key hubs. Our team is available 24/7 to ensure your vessel is safe and compliant anywhere in the world.

Contact our team or submit your request for calibration gases for gas analyzers on scrubbers here.

Sources:

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.