If you work in the marine industry or have any interest in maritime operations at all, you have probably heard about the US Coast Guard (USCG) and the Environmental Protection Agency (EPA), and their Vessel General Permit (VGP) requirements for Ballast Water Treatment Systems. The purpose of the VGP is to ensure that vessels sailing into US waters do not spread invasive species from other parts of the world when discharging their ballast water.

In a previously published guide for VGP, we explore everything one needs to know about this regulation and what shipowners and ship managers need to be aware of to remain compliant and avoid penalties.

The current article will focus solely on VGP Compliance Sampling, which is just one of the requirements, albeit a significant one, for vessels to achieve compliance in US waters. More specifically, we will describe our process of testing the ballast water in detail, so that you know what you should roughly expect if you ever find yourself sailing on American coasts, or if you just wish to know out of curiosity what this whole process entails.

The Steps of the Process

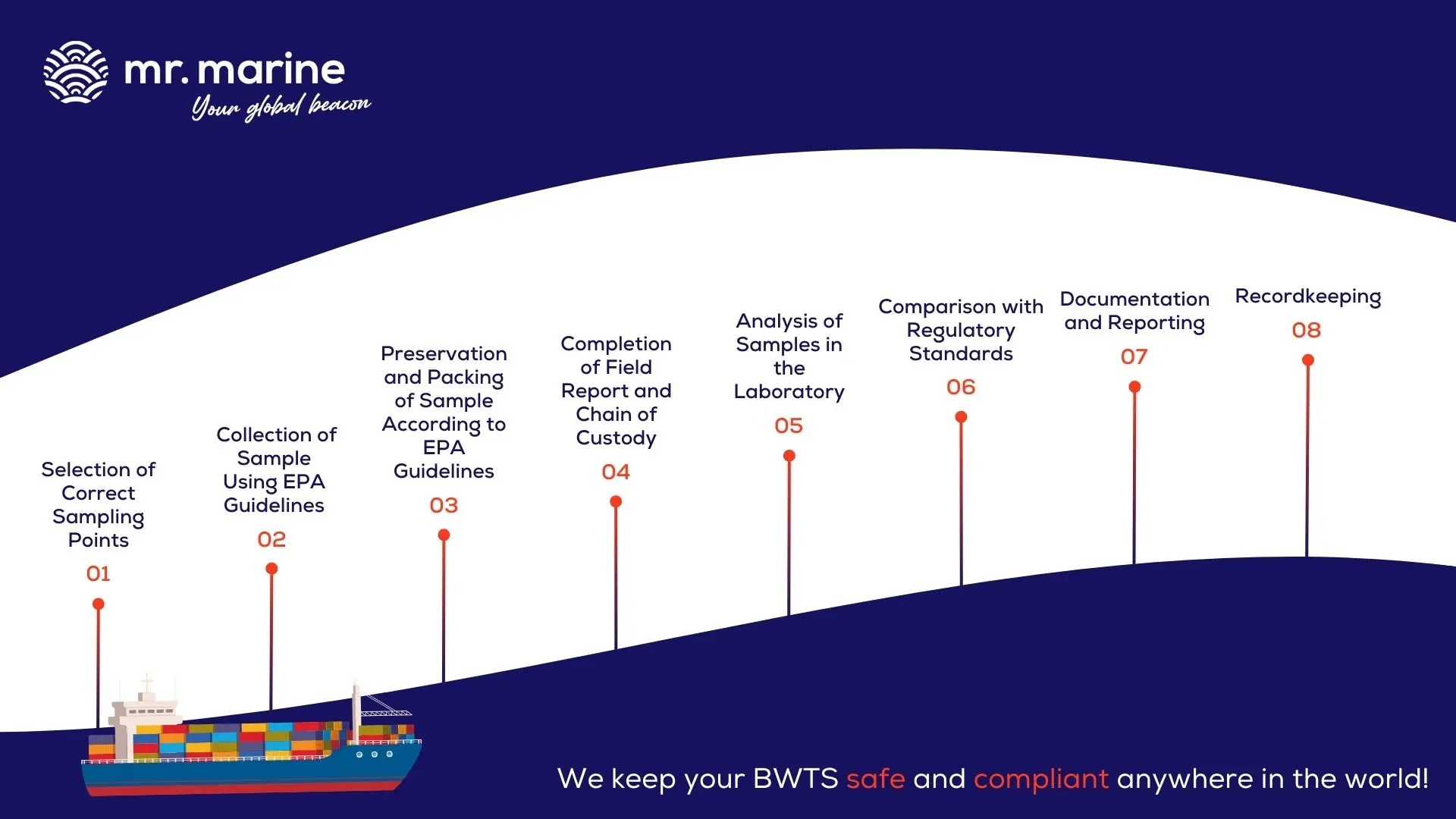

The VGP Compliance Testing process is divided into 8 steps, all of them equally important to achieve a desirable final result. Before diving into each individual step, here they are listed for a more comprehensive view:

- Selection of correct Sampling Points

- Sample Collection using EPA guidelines

- Sample Preservation and packing according to EPA guidelines

- Completion of field report and Chain of Custody

- Analysis of Samples in the laboratory

- Comparison with Regulatory Standards

- Documentation and Reporting

- Recordkeeping

1. Selection of Correct Sampling Points

Although it might sound straightforward, the selection of correct sampling points can be a challenging task if the person carrying it out is not an expert. Several things must be taken into consideration for the sample to be in accordance with the EPA’s recommendations. For instance, the sampling point should be strategically chosen to ensure representativeness of ballast water, including both inlet and outlet points, identifying mix zones in the water and considering high-risk areas. Additionally, methods such as computational fluid dynamics should ideally be employed when selecting the correct sampling points.

As a general approach, samples should be taken by using the in-line sampling points of the ships ballast water pipework. The sampling should be from a straight part of the discharge line as near to the ballast water discharge overboard as practicable.

2. Sample Collection Using EPA Guidelines

The collection of the samples also needs to follow specific guidelines set by the EPA. Numerous items are needed to carry out the collection of the water samples, including: sampling pole, sample bottles, field test equipment, buckets and disposable bucket liners, etc. The whole list set forth by the EPA contains at least 20 different items, which highlights the complexity of the process and why it is better to contact a specialized company for the VGP Compliance Sampling.

The collection of ballast water samples should follow specific guidelines, as set out by the EPA. Items such as sample bottles, pH field test equipment, preservation chemicals, 0.45 μm filters and additional filtering equipment are among the 20+ components required for a compliant procedure. Such practices will ensure a fully compliant VGP report which is acceptable to the EPA.

3. Sample Preservation and Packaging According to EPA Guidelines

This step represents a continuation of the previous one, because the samples have to be packed, labeled and preserved accordingly immediately after their collection. Similar to the last one, this step implies the use of items specified by the EPA, and strict rules must be followed, underscoring once again the importance of expertise and experience when conducting a proper and fully compliant ballast water sample collection.

4. Completion of Field Report and Chain of Custody

As the name of this step suggests, the next thing to be done after successful selection, collection, packaging and preservation of the ballast water samples is to complete a field report and a Chain of Custody form. This is part of the paperwork required by the EPA, and we take care of it ourselves for our clients when conducting the VGP Compliance Sampling.

5. Analysis of Samples in the Laboratory

Naturally, the next part of the process is taking the samples to the laboratory so the actual ‘testing’ takes place. Mr. Marine collaborates only with trustworthy, highly accurate laboratories that also take the EPA guidelines into consideration when performing the analysis. A major benefit here is that you don’t have to spend considerable time finding a laboratory and then also transporting the sample, as we will have it scheduled in no time and our experts will take the samples to be verified themselves.

6. Comparison with Regulatory Standards

Following the analysis, the obtained results need to be compared with the standards set by the VGP to determine whether the Ballast Water Treatment System is operating within acceptable limits and, thus, efficient in clearing the ballast water of unwanted microorganisms. This is the step which determines what further action needs to be taken by the shipowners and ship managers, because the requirements are different for vessels based on the analysis results. The sample must meet the standard in two consecutive tests for the vessel to be eligible for the annual VGP compliance sampling.

7. Documentation and Reporting

After the analysis results were compared to the VGP standards, Mr. Marine will fill out the necessary paperwork to document and report all of the performed activities. This documentation typically serves as a record of compliance efforts and may be required for regulatory reporting purposes.

8. Recordkeeping

Finally, we send our clients detailed records of all sampling and analysis activities, including field reports, Chain of Custody forms, laboratory results and compliance documentation. These records are essential for demonstrating compliance with regulatory requirements and may be subject to review by regulatory authorities.

Why Choose Mr. Marine for VGP Compliance Testing?

The first thing one probably notices after reading the whole process explained in detail above is that it sounds very tedious and complicated.

That is why we are here; to offer shipowners and ship managers a fully project-managed service, where everything is taken care of by us, from start to finish.

Even before the compliance testing itself, we will support you in finding the most cost-effective port for your vessel to conduct the testing in. So, the whole process will be fully coordinated and your efforts greatly diminished.

Contact us now and we can straight away devise a plan to get your vessels fully compliant with the VGP set forth by the USCG and EPA.